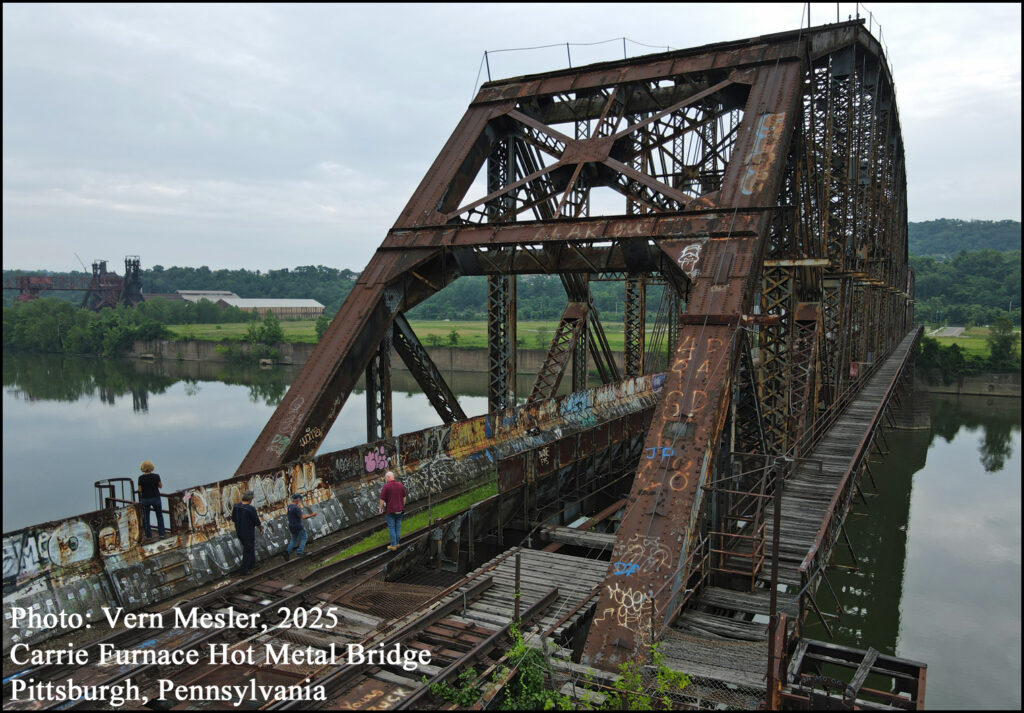

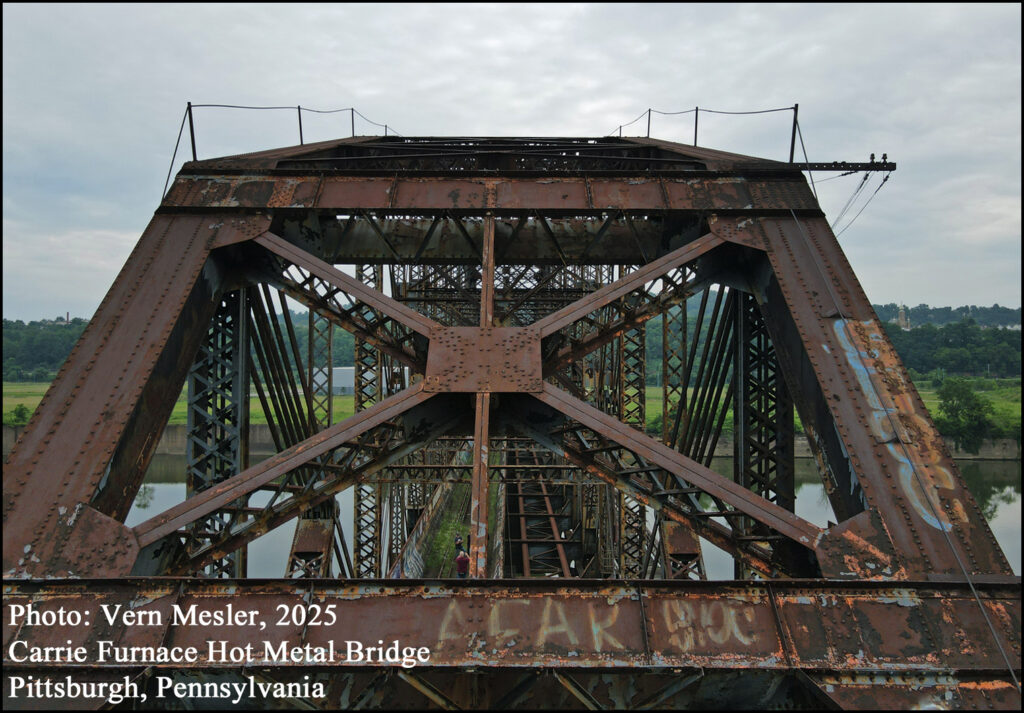

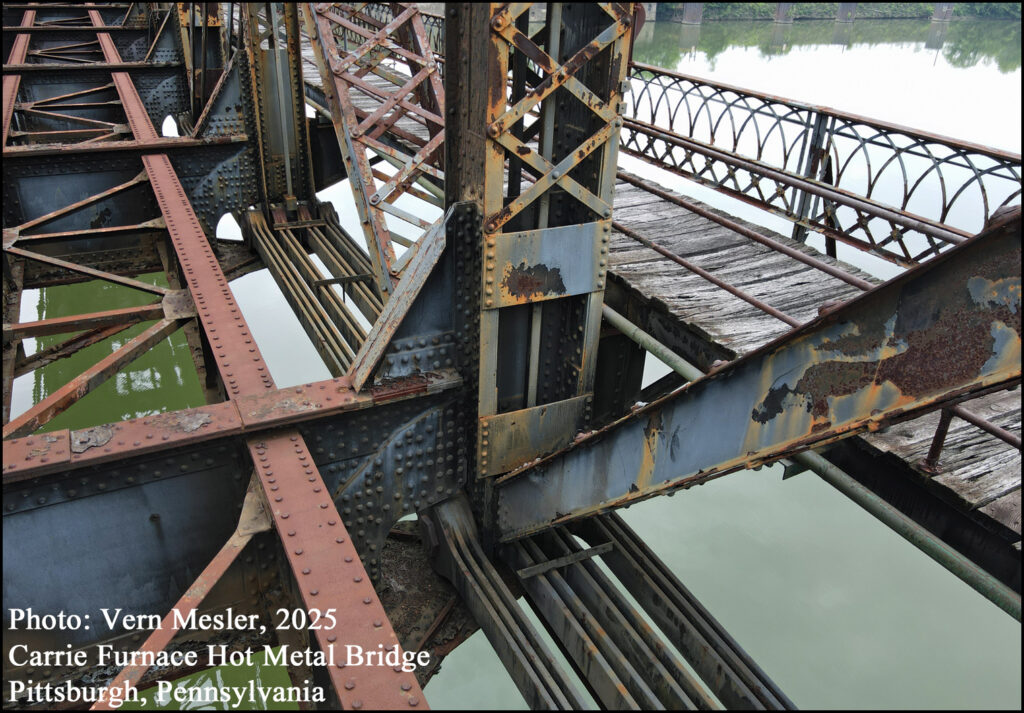

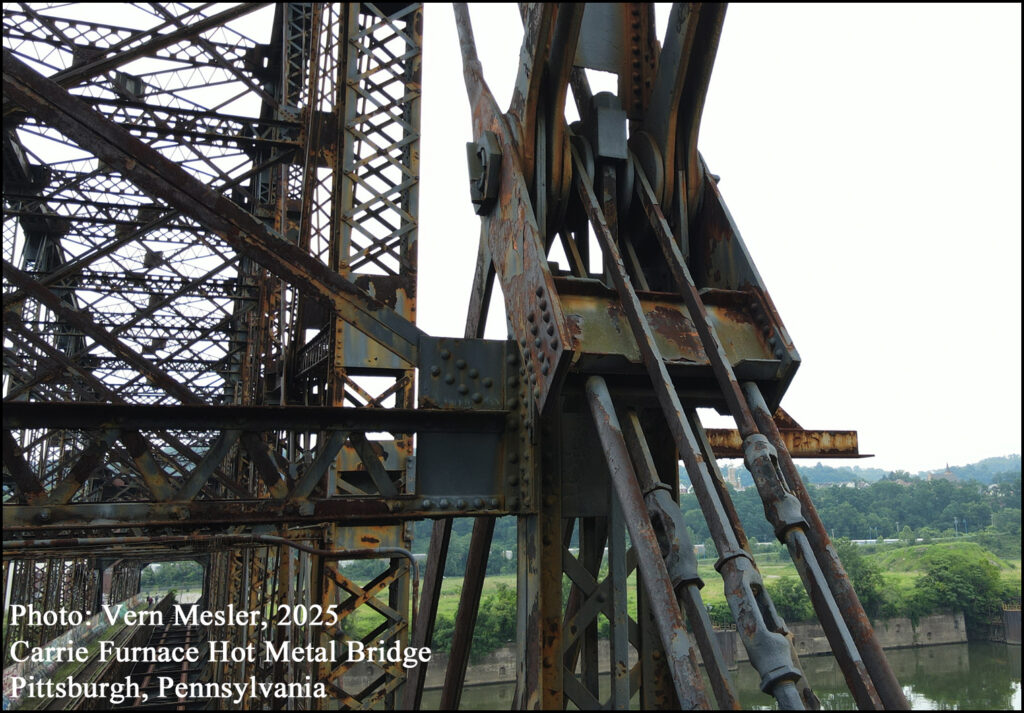

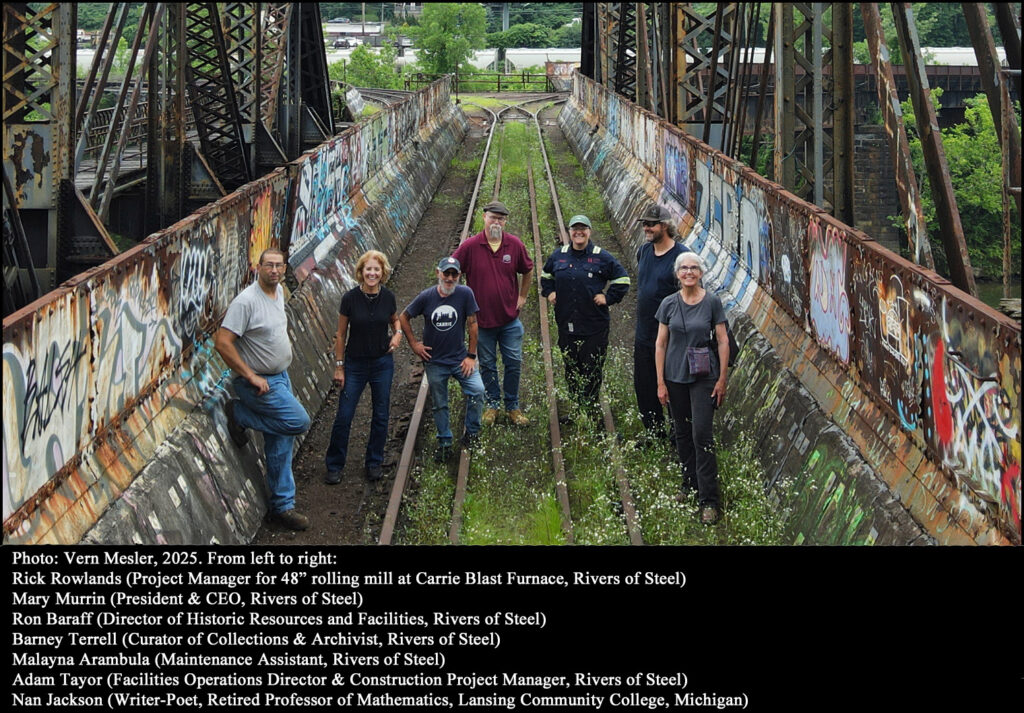

After a day of field riveting training at the Rivers of Steel Carrie Blast Furnace site, Facilities Operations Director Adam Taylor invited us on a private tour of the historic Carrie Hot Metal Bridge (currently closed to the public). I also had an opportunity to photograph details of the riveted connections of this famous, heavily shop-riveted bridge. Hot Metal bridges were a vital link in the making of steel in Pittsburgh’s early twentieth century steel mills. A description of a Hot Metal bridge is found in “The Bridges of Pittsburgh” by Joseph White (Engineer, Department of Public Works, Allegheny County, Pennsylvania) and M. W. von Bernewitz (Mining and Metallurgical Engineer, United States Bureau of Mines), published by Cramer Printing & Publishing Company, Crafton Station, Pittsburgh, Pennsylvania, 1928.

Hot-Metal Bridges (text from The Bridges of Pittsburgh by Joseph White and M. W. von Bernewitz, 1928)

Pittsburgh has three unique bridges – that is, their purpose is unique – spanning the Monongahela River: these are the three so-called and rightly so “hot-metal bridges” of the Jones & Laughlin Steel Corporation (one) and of the Union Railroad Company (United States Steel Corporation) (two).

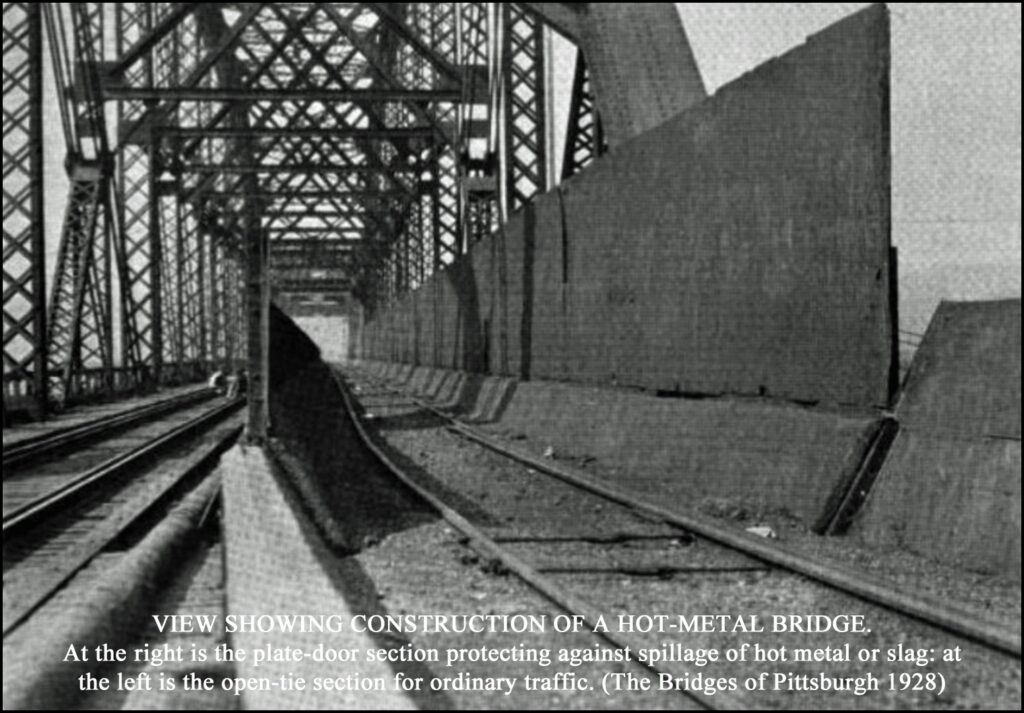

One of the many plants of the Jones & Laughlin Steel Corporation on the north side of the river are the six Eliza blast furnaces. They produce molten iron for the open-hearth furnaces and converters at the South Side Works, and this is hauled across the river over a through-truss, open-tie and plate-floor type of bridge. This was built in 1900 by the Edgemore Boiler Works and is 1161 feet in length. Of the five river spans the main span is 321 feet in length. When five blast furnaces are in operation, 24 trains a day cross the bridge. Each train is made up of a steam locomotive and two ladles each weighing 87 tons and carrying 90 tons of metal, and a caboose. In effect, every hour of the day about 180 tons of molten iron, or say 4300 tons a day, is hauled across the river for converting into steel.

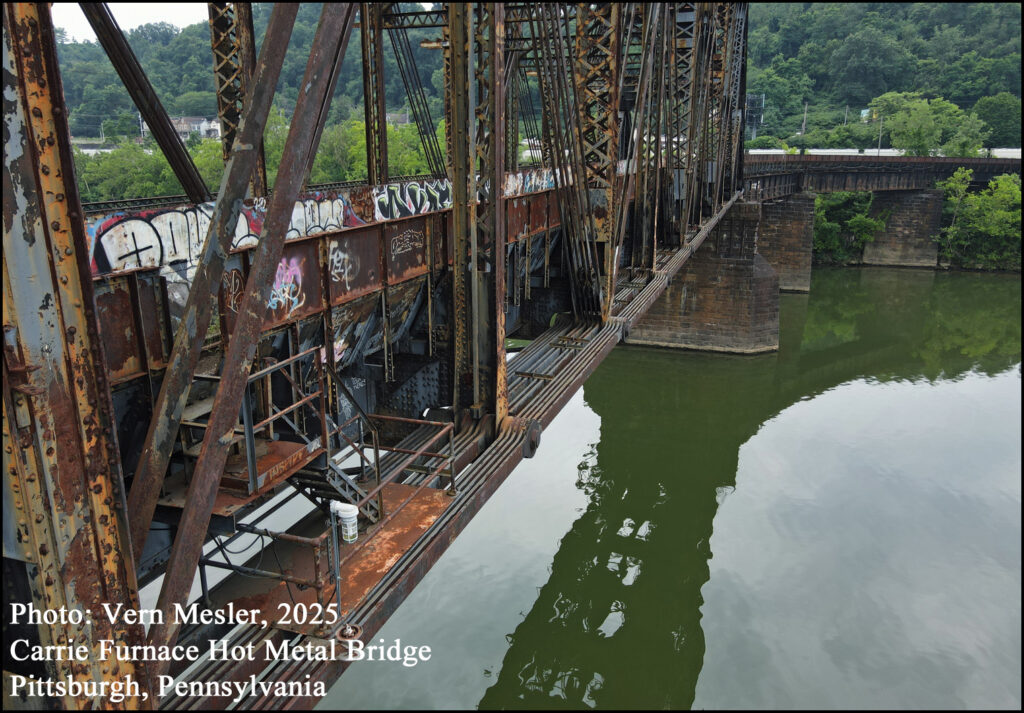

The bridge at Rankin is approached from the Carrie furnaces of the Carnegie Steel Company by an open-tie and plate-floor viaduct. From the Munhall end the bridge is approached by a single track Y. The Homestead or down-river leg of the Y is a combination of deck and through plate-girder spans with plate floor. The up-river leg is a combination of deck and through plate-girder span with open-tie floor. The hot-metal track throughout has side-plate protection on each side, excepting at the junction of the legs of the Y on the harbor line pier, where the protection is on the outside of each track and extends to the main truss spans.