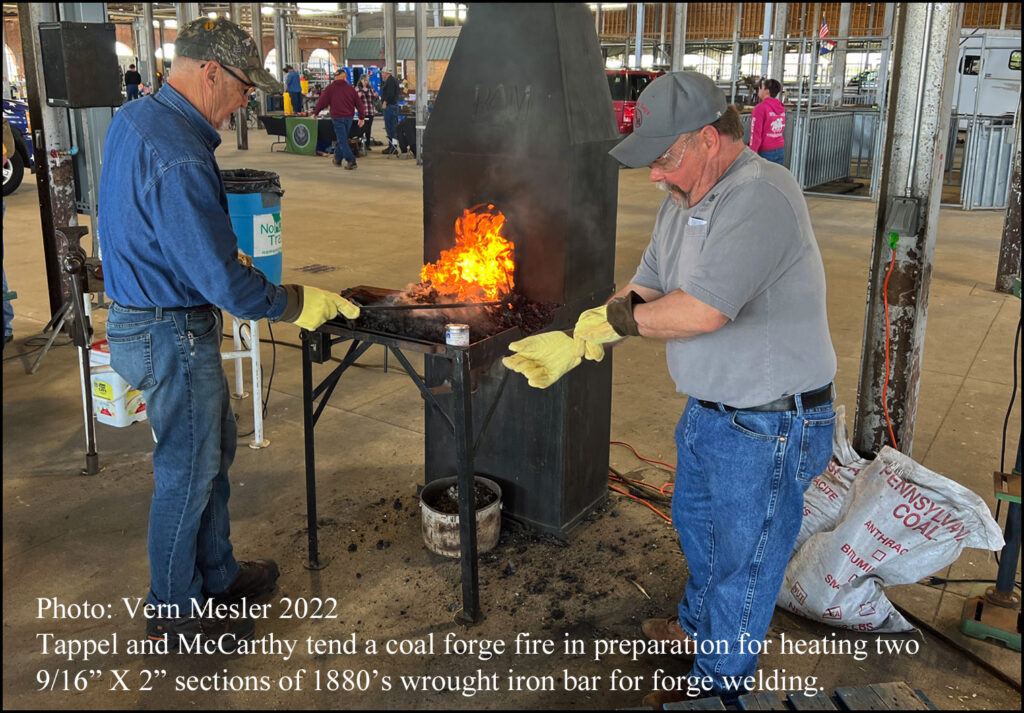

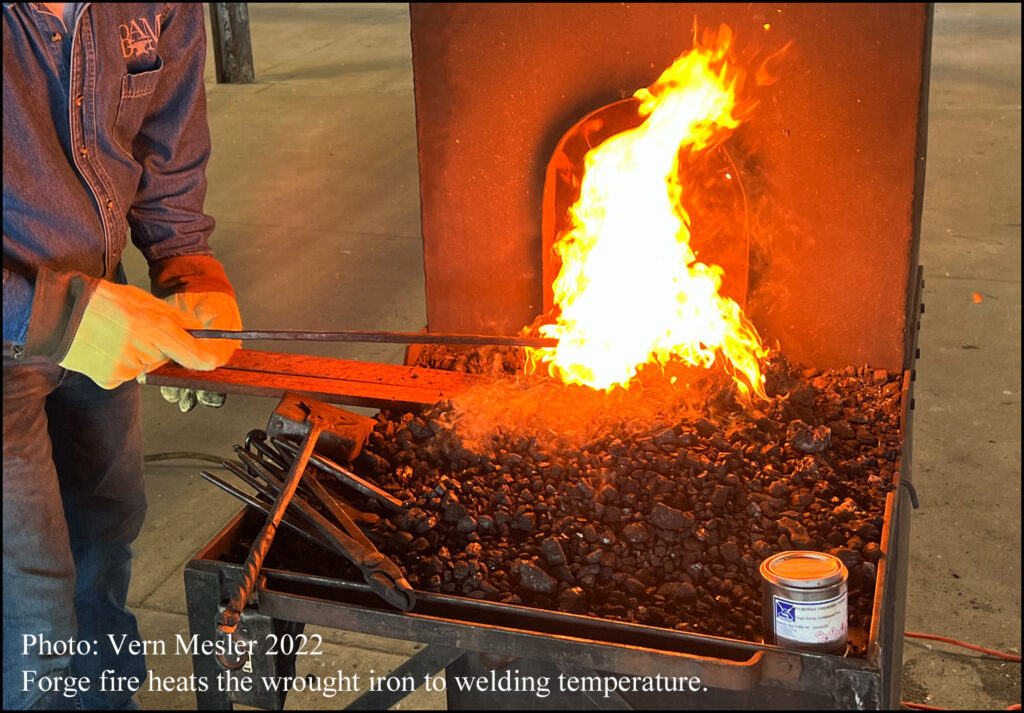

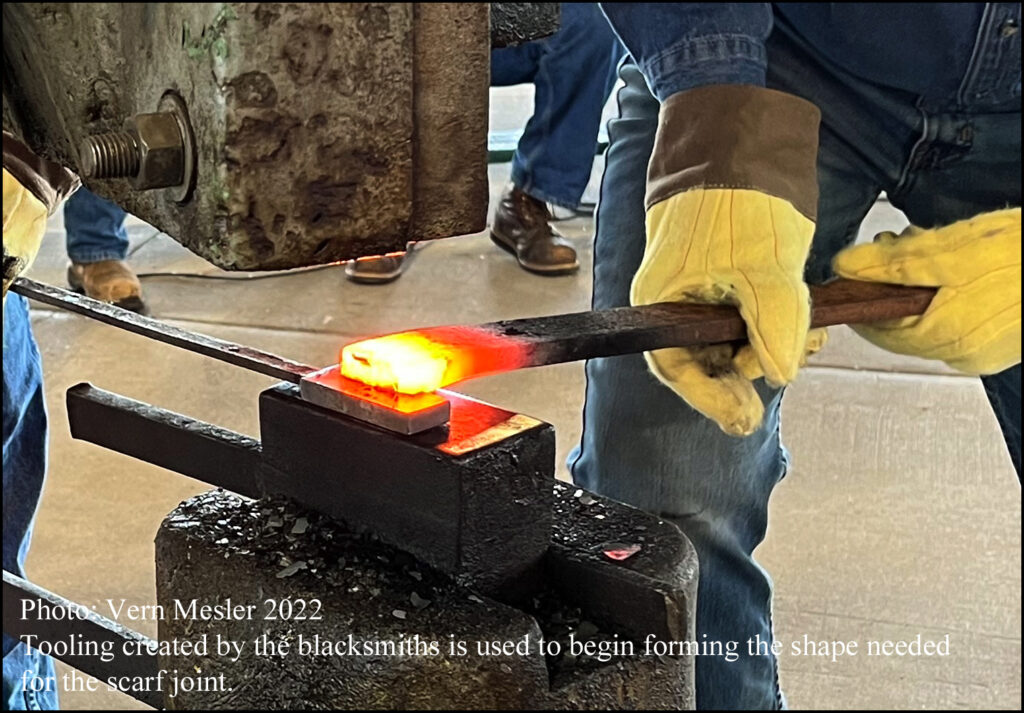

An April posting on Facebook showing the transportation of the 1942 Murray 100# Power Hammer (Vern) for the Blacksmith Association of Missouri (BAM) 30th Annual Ozark Conference in Sedalia, Missouri, led to our decision to attend the BAM event. It was one of those quick decisions that proved to be an important educational experience for me in my search for those unwritten craftsmen’s records of the late nineteenth and early twentieth century fabrication processes. Forge welding is a process used in the fabrication of many of the critical members of historic iron structures, and it is the least known process used in the fabrication of these members. What were the tools and fixtures and methods used for producing a forge weld? During an email exchange with Bernie Tappel (an experienced blacksmith and member of BAM), I asked: if I brought some wrought iron sections to the event, could I get them forge welded with the 100# Murray. “Sure, we can find someone to do that,” Tappel responded. He and fellow blacksmiths and members of BAM Steve McCarthy and Ken Jansen accepted the challenge and produced a successful forge weld using those craftsmen skills of sight, sound, and touch.