Cut River Bridge Repairs

(Heath M. Robinson Memorial Cut River Bridge)

Mackinac County, Michigan

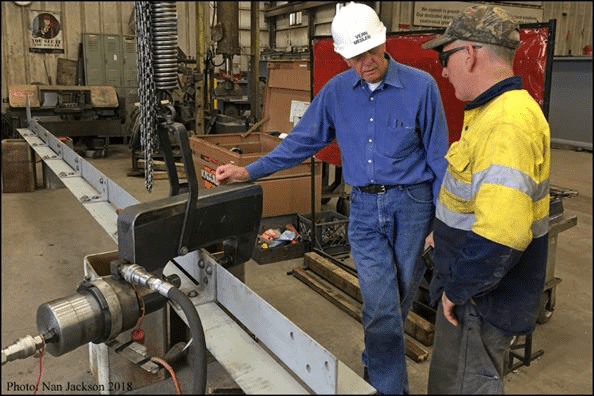

Steve describes the hydraulic press he custom built for the Cut River Bridge project.

“It honors the intent of the original engineering design and craftsmen that fabricated and erected the structure.” Lloyd Baldwin, cultural and historic resource coordinator for Michigan Department of Transportation, comments on the replication of riveted structural members for the Cut River Bridge in Michigan’s Upper Peninsula. The MDOT project involves painting, structural steel repairs, miscellaneous road repairs and the replication of riveted sections that will preserve this structure as an accurate historic record as well as a functioning bridge for highway vehicular traffic. Baldwin has been an early advocate for field rivet repairs and the replication of riveted sections for the replacement of worn or damaged sections on the Cut River Bridge. The shop-riveting done at Wisconsin Structural Steel Company in Barronett, Wisconsin, is an innovative approach to the preservation of historic riveted truss bridges currently in service. “The MDOT – State Historic Preservation Office (SHPO) collaboration is achieving successful projects that balance the historic preservation standards with current safety and performance standards,” Baldwin notes.

In July, my wife Nan Jackson and I traveled to Barronett to tour the Wisconsin Structural Steel Company/LeJeune Steel to observe the shop riveting being done by Steve Howell of Ballard Forge, Seattle, Washington. The next day we visited the Cut River Bridge job site to view where a pack rust removal procedure will be performed.

During our visit at WISSCO, Plant Manager Brad Fox led us on an informative and spirited tour of the plant production facilities. Fox described the integration of advanced Peddinghaus CNC machinery with shop floor fabrication production, featured in Peddinghaus, Steel Fabrications’ Review, Autumn 2011, as “Textbook Bridge Fabrication”: “Together with their heavy fabrication division, Wisconsin Structural Steel, LeJeune, is a prime example of what modern technology and traditional craftsmanship can do in today’s economy.”

We would like to thank those who made it possible for us to visit the Wisconsin Structural Steel Company (Brad Fox and Steve Howell) and the Cut River Bridge job site (Chris Rupinski, MDOT Engineer Manager, Newberry TSC; and Stacy Sutela, MDOT Bridge Inspector, Newberry TSC).