In a large high-ceilinged industrial style building, a steel table with a heavy grated top is rolled into position in preparation for another field riveting demonstration at Lansing Community College. Alongside the table, atop a high stand made of steel, a forge is fired up with an industrial gas, fueling a T-Rex Burner, correctly adjusted to a neutral flame to heat steel rivets. At the end of the table, on a steel rack, lays a number-sixty field-riveting hammer primed with a hundred and twenty pounds of compressed air. On top of the table and bolted to the heavy grated top is a rivet fixture that allows for the driving of rivets and the removal of the driven rivets, then is bolted back together to drive more rivets. On a steel layout table nearby is a twenty-eight-pound industrial tool, two-foot of heavy tool steel; when its trigger is pressed a powerful surge of air drives an internal piston against a long chisel, snapping off the head of cold rivets. For those who operate this industrial tool in the field, it’s known as a Hell Dog.

This field riveting demonstration is led by industrial craftsmen who are Lansing Community College educators in the industrial art of welding. Their expertise and experience provides students with advanced shop knowledge for a successful career in industry.

Even in the 21st century, there is a value for Technical Careers students to learn about the industrial riveting process. The American Institute of Steel Construction (AISC) recognizes the importance for the engineering community to be knowledgeable about riveted connections, as stated in their “Guide to Design Criteria for Bolted and Riveted Joints” in item 3.1 RIVET TYPES: “Riveting is among the oldest methods of joining materials, dating back as far as the use of metals in construction practice. Rivets were the most popular fasteners during the first half of this century, but their use has declined steadily since the introduction of the high-strength bolts. At the present time they are rarely used in either field or shop connections; either high-strength bolts or welds are used almost exclusively in new work. Nevertheless, the increasing importance of evaluation and retrofitting of existing structures will require that the designer be knowledgeable about riveted connections” (emphasis added).

The students being introduced to this industrial process will have more knowledge of the field and shop riveting process when working on a riveted bridge or building than many of the engineers responsible for the design work.

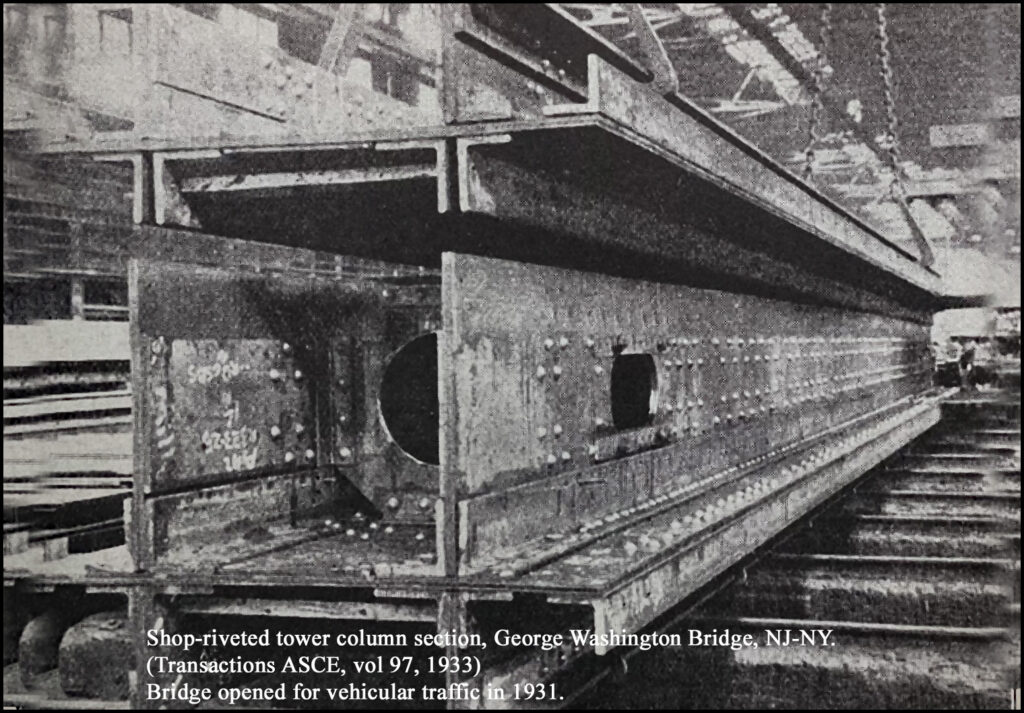

The industrial shop riveting process is found not only in nineteenth century wrought iron bridges, but also in thousands of major shop-riveted highway bridges fabricated through the mid-twentieth century that still provide safe and dependable service, and will, if properly maintained, serve well into the future.